Communicating with instruments using a PLC controller

2025-06-04

Overview

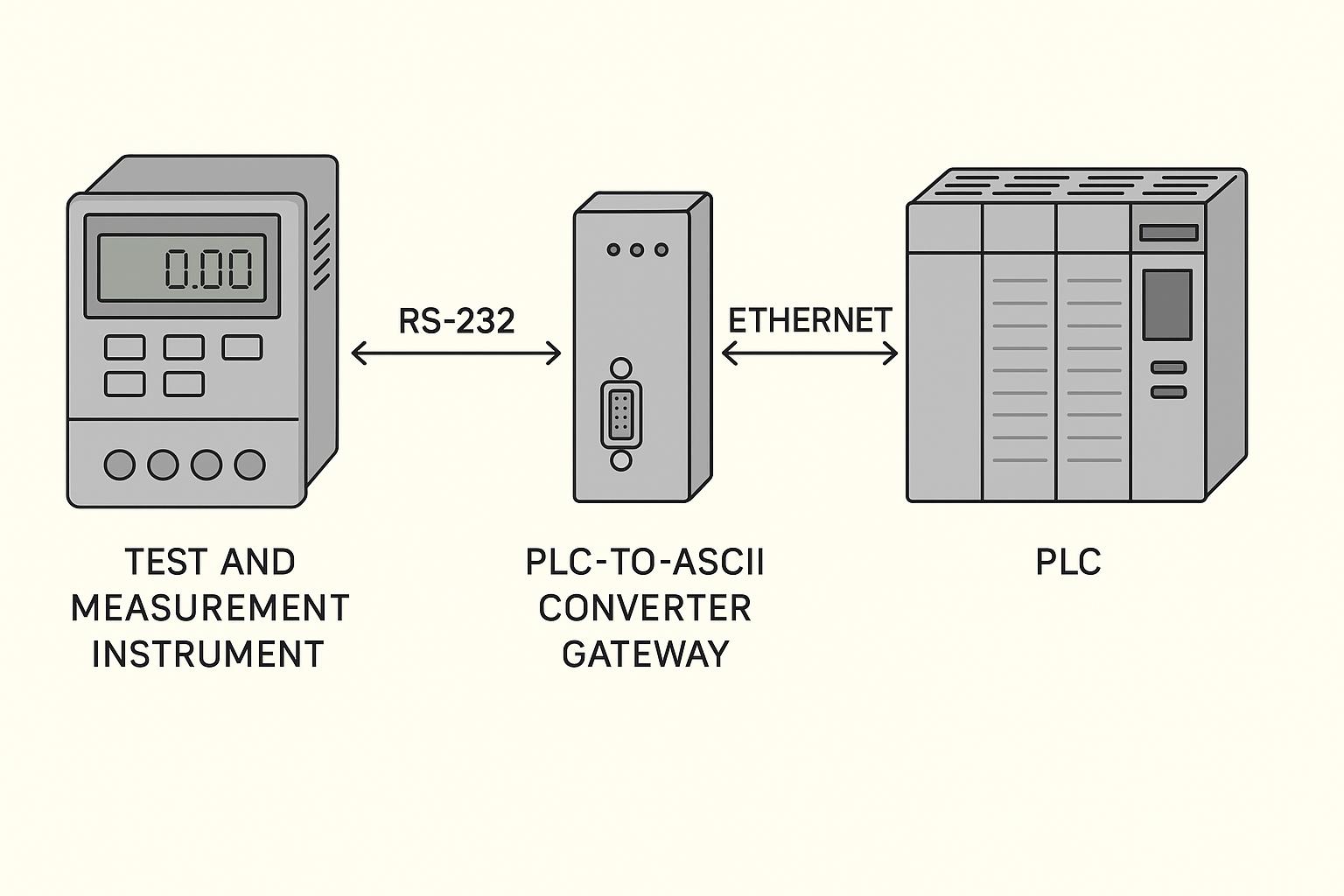

Many B&K Precision instruments support remote control and data communication through their RS232 port, which can be integrated into automated systems using a programmable logic controller (PLC). In some cases, direct communication between the PLC and the instrument is not possible due to differing communication protocols, especially when the instrument uses ASCII serial data.

Using a PLC-to-ASCII Gateway

To bridge this gap, a PLC-to-ASCII converter gateway can be used. These gateways translate ASCII serial communication from the instrument’s RS232 port into a format the PLC can understand. We’ve seen reliable results using the 435NBX-N700-D from Real Time Automation (RTA), which converts ASCII to formats compatible with Allen-Bradley PLCs.

Basic Setup

Here’s a typical communication chain setup:

- B&K Precision instrument sends ASCII serial data via RS232.

- The RTA 435NBX gateway receives the ASCII data.

- The gateway converts it to a format readable by the PLC.

- The PLC processes or logs the incoming data as needed.

Additional Notes

- The gateway supports configuration through a web interface.

- Make sure your instrument’s serial settings (baud rate, stop bits, etc.) match what the converter expects.

- You may need to write a small ladder logic program or structured text code in the PLC to read incoming strings.

- If you need assistance with using an instrument’s Ethernet/LAN interface, you can open a Technical Support Ticket here: https://www.bkprecision.com/support/request/technician